In many ways, concrete is an inherently sustainable construction material. It’s relatively simple to manufacture and uses only three main ingredients: water, aggregate, and cement. The aggregate is primarily composed of crushed gravel and sand, which accounts for roughly 90% of the concrete material once mixed with water. So it’s that last ~10%, the cement mixture, which is the true nemesis of concrete’s eco-friendliness.

However, helping to offset that environmental impact, concrete can generally be broken down and recycled or reused with relative ease. So when you compare it to the complex modern manufacturing processes and materials needed for e.g. plastics, electronics, or oil and gas refinement, concrete production seems positively green.

Putting the Concrete Industry’s Global Carbon Emissions into Perspective

Nevertheless, concrete accounts for a huge percentage of humanity’s total greenhouse gas emissions globally – mostly due to the sheer amount of concrete that we use. (In fact, concrete is commonly cited as the most-consumed material in the world after only water.) The cement industry alone is responsible for about 8% of planet-warming carbon dioxide emissions – far more than emissions from the entire aviation industry. To put it into perspective: if the cement industry were a country, it would be the third-largest emitter of carbon dioxide in the world, after the U.S. and China.

The challenge, then, is to take this environmentally-friendly material that we depend on as a society and make it more durable and dependable, longer-lasting, and thus more sustainable for the future. Enter Hycrete’s innovative treated concrete solutions.

Hycrete Treated Concrete Is the Eco-Friendly Building Solution:

As a society, we need to make sure we maximize the durability of the structures we build using concrete – for public safety, economics, and of course the environment. Built correctly, concrete structures will last far longer than most other construction methods. Consider this: concrete structures built by the Romans illustrate how long concrete can last if done properly.

Hycrete improves the durability of concrete which makes the cost benefit equation of using concrete (an irreplaceable material for modern life) more balanced. Unlike many traditional concrete protection options, Hycrete offers enhanced permanent protection for the lifetime of the structure. Essentially, Hycrete eliminates many of the costly, time-consuming surface maintenance procedures otherwise needed in building upkeep. Weathering, freeze-thaw cycles and corrosion are all kept at bay, preserving both the structural performance and aesthetics of the concrete exterior.

Generally costing 20% to 30% less than a conventional installed membrane, Hycrete is not only the functional and environmentally-sound solution – it’s the economic winner as well, ensuring better long-term ROI. With a longer life-cycle and smaller carbon footprint, Hycrete is Cradle to Cradle certified for achieving a positive environmental impact.

Waterproof Protection for a Longer-Lasting Structure

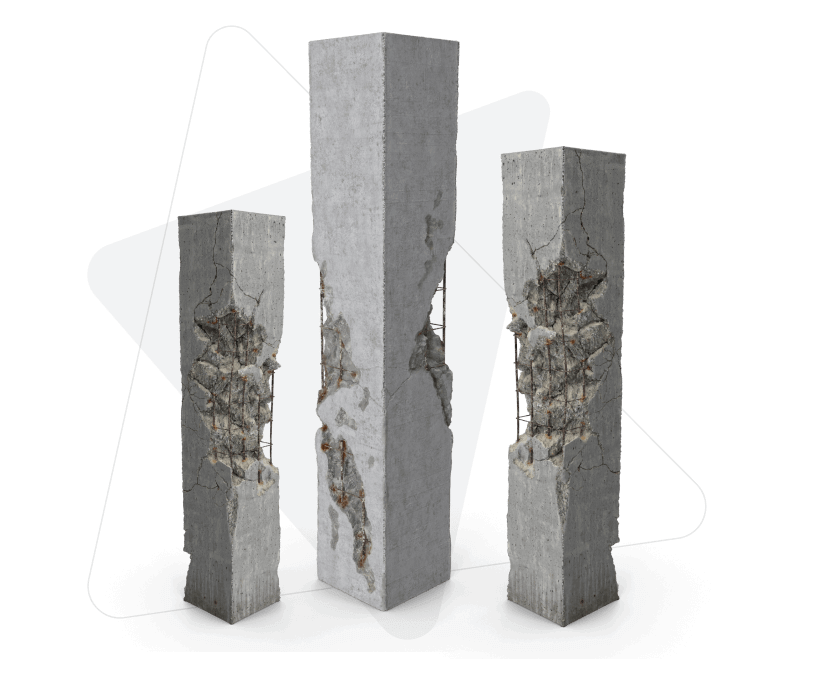

Hycrete is specially engineered to maximize surface protection. Hycrete, a hydrophobic pore-blocking admixture, prevents water from working its way into the concrete – which will otherwise lead to corrosion and material breakdown. Hycrete is especially crucial for winter climates, in which the freeze-thaw cycles can easily lead to cracking when water is allowed through the surface. No matter the climate, Hycrete can extend the life of virtually any building and thus reduce the environmental impact of both construction and maintenance.

Chloride diffusion testing is one of the most important methods of determining a product’s efficacy in reducing corrosion/deterioration. Hycrete has been proven to reduce chloride diffusion and extend concrete life. Tourney Consulting Group (TCG) independently performed bulk chloride diffusion testing. The result was Hycrete outperforming both the control and the other waterproofing admixtures by reducing chloride diffusion by a factor of 3.8 to 7.0 times.

As an additional case in point, one of our projects recently hit its 10-year anniversary and achieved Living Building Registration – the Bullitt Center in Seattle, dubbed “the Greenest Commercial Building in the World”. With the help of Hycrete, the building is designed to hit a 250-year lifespan, and is continuing to perform at an even higher level of efficiency than expected.

Concrete Protection that Extends Far Beneath the Surface

Hycrete’s protective properties extend far beyond the surface of the structure. It also creates what we call a “liquid green bar” as Hycrete chemically reacts with the surface of internal steel reinforcement elements. As a result, Hycrete automatically forms a corrosion-inhibiting molecular barrier around rebar, preserving structural integrity and reducing long-term maintenance requirements. (We recently teamed up with LMN on the massive Seattle Aquarium addition, which uses a huge amount of curved rebar protected from the elements with Hycrete.)

As an added benefit, Hycrete protection is not susceptible to dings, gaps, or other imperfections which are common with conventional epoxy-coated rebar. Hycrete also does not degrade over time, further reducing the structure’s lifetime carbon footprint. Case in point: Hycrete was the chosen treatment option for Bridge V-39 in Sussex County, New Jersey. With advanced hydrophobic permeability-reducing admixtures, Hycrete is calculated to extend Bridge V-39’s useful life by 66% when compared to conventional rehabilitation methods, saving more than 50% versus the cost of a deck replacement.

Minimizing Material Use and Reducing Waste in Construction

Stronger, longer-lasting buildings mean that less construction materials are used, and thus the industry produces less overall waste. By maximizing construction integrity, Hycrete is an inherently green treatment technology, engineered to achieve the industry’s future goals of reduced carbon emissions and material usage.

Easier, More Efficient Concrete Recycling

Of course, recycling and reuse are critical factors in any calculation on environmental impact. By eliminating adhered membranes common in many modern construction applications, Hycrete actually makes concrete even easier to recycle. In fact, the practical, straightforward recycling process of Hycrete is what makes concrete recycling possible in some jurisdictions with otherwise limited capabilities in material processing.

American Engineered Innovation for the Modern Construction Sector

Hycrete is an innovative American manufacturer founded in 2003. Our company’s mission is to help the construction industry build better, more sustainable structures through the engineering of better concrete materials. Now backed by more than two decades of experience and thousands of successful projects, Hycrete has become the scientifically-proven gold standard for concrete waterproofing and corrosion protection.