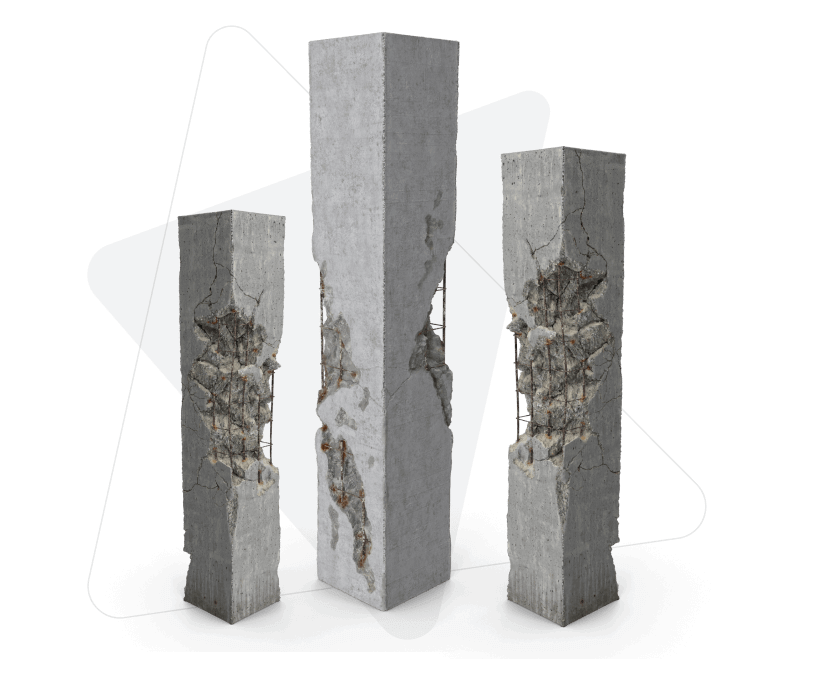

When left unchecked, corrosion in concrete steel reinforcement adds up to extremely costly building maintenance and repairs. Corrosion typically begins when moisture is wicked through the concrete via capillary absorption, then proceeds down until it reaches the steel reinforcement elements.

Rebar corrosion inevitably compromises the structural integrity of the building, requiring extensive repairs or full-on replacement of the affected areas. Plus, that’s in addition to all of the cosmetic damage that comes with corrosion – staining, spalling, surface cracking, etc. – which can severely devalue your property before structural issues even arise.

Today’s building owners and construction contractors therefore need a more comprehensive solution that cuts corrosion off at the source. That’s where Hycrete admixtures come in, with advanced waterproofing and corrosion protection that reduces, if not eliminates the need for ongoing maintenance and repairs. Concrete treated with our cutting-edge hydrophobic technology will last longer, look better, and preserve the value of the property investment for decades to come.

Let’s take a closer look at some of the advanced concrete protection options that help the modern industry maintain better building aesthetics, structural longevity, and higher sustainability.

Why Standard Surface Treatments and Installed Membranes Won’t Cut It

Many concrete protection strategies are effectively just skin deep, focusing solely on the surface of the structure. These options include standard surface coatings, basic concrete treatments, and installed membranes – all of which are designed to keep outside water from reaching further down into the concrete.

Surface coatings naturally wear out over time. Maintaining protection therefore requires costly, time-consuming surface preparation and replacement. On the other hand, installed membranes are prone to improper application due to the complexity of the installation process. Moreover, the membrane itself can often become damaged through unrelated building maintenance or work by other trades.

All of these issues ultimately result in subpar weatherproofing and the need for additional ongoing repairs – unlike the long-term, comprehensive solution that Hycrete provides.

Complete Protection from Moisture Intrusion Is The Key to Longevity and Sustainability

Concrete is highly porous, so water and corrosive elements will always find their way through over time. This is why chloride-induced corrosion is one of the most common modes of structural damage. Furthermore, concrete is prone to carbonation, which reduces the pH of the material and makes any steel reinforcement elements inside susceptible to further corrosion.

So, preventing carbonation and chloride-induced corrosion in reinforced concrete is critical throughout the modern construction sector. Clearly, a more comprehensive method of waterproofing and corrosion-resistance is needed to eliminate the need for constant maintenance, repairs, and retreatments.

A Hydrophobic, Corrosion-Resistant Concrete Admixture for Comprehensive Protection

Hycrete admixtures go much deeper than standard surface treatments and installed membranes. Engineered with our advanced chemistry of protectants and a dual-action corrosion inhibitor, Hycrete permanently protects the structure from the inside out.

When mixed with concrete, Hycrete’s unique hydrophobic admixture forms a copolymer that fills the pores and capillaries in the material, making concrete virtually non-porous and resistant to moisture. Engineered to last the lifetime of the structure, there is no reapplication required. Meanwhile, the risk of damage is therefore mitigated, and ongoing maintenance is kept to a minimum.

Hycrete reacts with the metallic ions in cement and rebar to form an internal corrosion-inhibiting surface coating around steel reinforcement. Hycrete is a water-based admixture for the protection of concrete that extends the life-cycle of concrete structures, allows post-life concrete to be recycled, and earns valuable LEED credits for green building projects.

Combining Waterproofing Strategies for Multi-Level Protection

For building projects that require virtually zero water ingress, Hycrete can be used in conjunction with a waterproof membrane serving as a backup system. For example, Disney’s new headquarters in downtown New York City houses some high-tech, highly sensitive recording studios located at the basement level, demanding complete protection from the outside elements. This state-of-the-art building combines Hycrete with a waterproof membrane to yield the ultimate level of long-term protection.

Short-Term Protection Options: Concrete Sealant and Surface Treatments

Additionally, there are multiple concrete sealing options for above-grade applications. These options lack the total protection and longevity of more advanced concrete protection strategies. Simply put these options are just as they are classified, short-term.

Film-Forming Concrete Sealers and Coatings

Film-forming sealers, or concrete film coatings, are surface treatments designed to seal out the elements while providing basic protection against wear and abrasion. Compared to other concrete protection strategies film coatings are less of a long-term solution, requiring periodic reapplication as the film wears away. However, the bigger performance issue is due to the fact that the sealer only adheres to the pores on the surface of the concrete. In other words, the protective barrier is essentially only skin deep, preserving looks and aesthetics without truly benefiting overall structural integrity.

Penetrating Concrete Sealers and Coatings

As the name suggests, penetrating sealers are engineered to reach beneath the concrete surface to protect the material from water ingress and contaminants, helping to prevent both surface stains and cracks. However, like film-forming surface coatings, the level of protection and longevity cannot compete with the more comprehensive concrete protection options we’ve discussed. Penetrating sealers are therefore generally used for indoor applications, or less demanding outdoor applications which simply require a basic shield from the elements rather than full structural protection.

While concrete sealants and surface treatments offer varying levels of protection against the elements, they lack the dual-level waterproofing and long-term corrosion prevention that Hycrete delivers.

Engineering More Effective and Sustainable Concrete Protection Strategies Since 2003

Hycrete is an innovative American manufacturer founded in 2003 with the aim of developing the best, most sustainable concrete protection strategies possible. For more than two decades we have helped the construction industry achieve better, more sustainable buildings through the engineering of innovative concrete admixtures.