Case Study

Kuwait Naval Base (KNB) Breakwater and Cargo Repair

Introduction

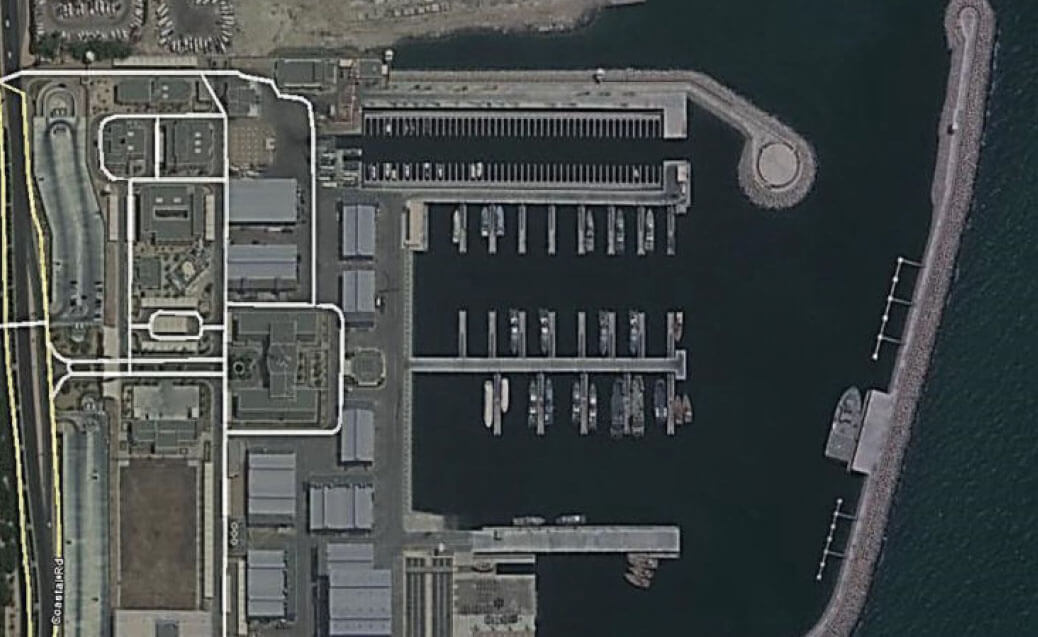

Kuwait Naval Base (KNB) was originally constructed in the late 1970's and over the last 35 years the superstructure of the south breakwater and the cargo pier, which is accessed from the breakwater has fallen into disrepair. There is significant cracking and various types of damage to the concrete superstructure of the breakwater. The breakwater is approximately 1.0 kilometers in length and creates an artificial harbor for the portside operations of KNB. The breakwater supports a roadway allowing traffic to the head of the breakwater, as well as various utilities.

HYCRETE PROVIDES LONG-TERM CONCRETE PROTECTION

Structure:

breakwater - artificial harbor

Applications:

1.0 kil in length artificial harbor

Architect:

PRSP Architects

Engineer:

SY2 Associates

General Contractor:

TOA Corporation

Owner - Developer:

US Army Corps of Engineers Middle East

Ready Mix Provider:

Kuwait British Ready-Mix Co.

Product Type:

Testing Labs:

SIMCO & INCO

Hycrete Partner:

Baxel Construction Materials Co.

Testing Software:

STADIUM

Challenge

The foundation and superstructure design for the Breakwater aims to extend its service life by 25 years. Additionally, the reconstructed cargo pier and alternate pier are designed for a service life of 50 years. In this context, service life refers to the expected lifetime of the structures without requiring significant rehabilitation or major repairs.

Overview

Summary

Solution

The original design mix, initially qualified for breakwater structures with a 25-year serviceable life under splash conditions, underwent adjustments. By incorporating Hycrete as a dual-action corrosion inhibitor and waterproofing admixture, the mix became suitable for pier structures with a 50-year serviceable life under tidal conditions. Samples were submitted for testing to SIMCO and INCO. Notably, the conventional approach of service life analysis was replaced by STADIUM, a sophisticated numerical modeling tool. STADIUM considers various factors, including chloride ingress and other contaminants, to predict concrete degradation kinetics and estimate time before reinforcing steel corrosion initiation. This innovative method enhances accuracy and informs decisions related to material design, quality assurance, and overall service life management.

Material Savings

Time Savings

Result

1.Hycrete used in the breakwater structure can achieve compressive strength >35MPa at 56 days and provide >25 years of durability for 75mm concrete cover when exposed to splash conditions, which satisfies the contract's requirement. 2.Hycrete used in the pier structure can achieve compressive strength >35MPa at 56 days and provide >50 years of durability for75mm concrete cover when exposed to splash conditions, which satisfies the contract requirement. 3.Hycrete + Synthetic Fiber used in the breakwater foundation repair can achieve a compressive strength >42MPa at 56 days and provide >25 years of durability for 75mm concrete cover when exposed to tidal conditions, which satisfies the contract's requirement.

More Case Studies

Thousands of Success Stories Worldwide

How to Get Started

See How Hycrete Can Impact Your Project

- Get Reviewed

- Get Protected

- Get Supported