Hycrete has long been the leading choice in long-term concrete protection for the American transportation sector and beyond. From bridges and decks to roadways and barriers, our chemically-advanced admixtures have extended the life of critical infrastructure across the nation for more than 20 years.

In fact, it was just over a decade ago that Hycrete celebrated its first 10-year landmark of helping DOTs succeed throughout the industry. Commenting on that success at the time, Hycrete’s president Jason Tuerack said:

“Our challenge is to save developers and DOTs money wasted on costly repairs and help them to increase their earnings or give them the freedom to reallocate funds from repairs to improvements. By extending the structural and cosmetic life of concrete, I am confident that Hycrete’s customers can reap these benefits.”

In the 11 years since that statement, Hycrete has only reaffirmed its position as the most effective method for comprehensive concrete protection and corrosion prevention.

Hycrete Now Caltrans Approved – California Department of Transportation

In addition to the various DOT testing and state approvals discussed below, one of the latest and most exciting developments is that Hycrete Endure CP is now approved by the California Department of Transportation. Considering California’s nation-leading commitment to green initiatives, Caltrans approval further solidifies Hycrete’s position as the most effective and sustainable concrete protection for highways and infrastructure.

Exceeding AASHTO Requirements for Bridge Decks and Roadways

As discussed in one of our previous blogs, Hycrete is approved by the American Association of State Highway and Transportation Officials (AASHTO). In testing, our admixture met or exceeded all AASHTO requirements for use on bridge decks and roadway infrastructure. This approval is for use as a Type S admixture under the AASHTO’s specific guidelines regarding Chemical Admixtures for Concrete.

Case Studies in Concrete Protection and DOT Testing:

Virginia DOT – Determination of Capillary Absorption ASTM C1585

The VTRC of the Virginia DOT conducted extensive testing of Hycrete admixtures, including the ASTM C1585 absorption test. In this critical test for determining water absorption rates, Hycrete demonstrated up to six times lower absorption compared to standard concrete mixtures. The testing was conducted with the Virginia DOT’s standard A4 high-performance concrete (HPC) mixes with variations in Hycrete dosage and the inclusion of fly ash. (Research Council (VTRC), Virginia Dept of Transportation – May, 2007)

New Jersey DOT – Reduction of Chloride Penetration at All Depths

The New Jersey DOT installed test bridge decks on Route 130 in 2006. The control deck utilized the standard NJ DOT high-performance concrete (HPC) mix, while the test deck utilized Hycrete admixtures.

Core samples taken in late 2009 show a dramatic benefit in chloride resistance in the Hycrete deck. Chloride concentrations in the Hycrete deck were up to 3.5 times lower. A Hycrete-treated deck could be expected to be considerably more durable than a deck constructed with the standard DOT HPC mix design. (Tourney Consulting Group (TCG) – December, 2009)

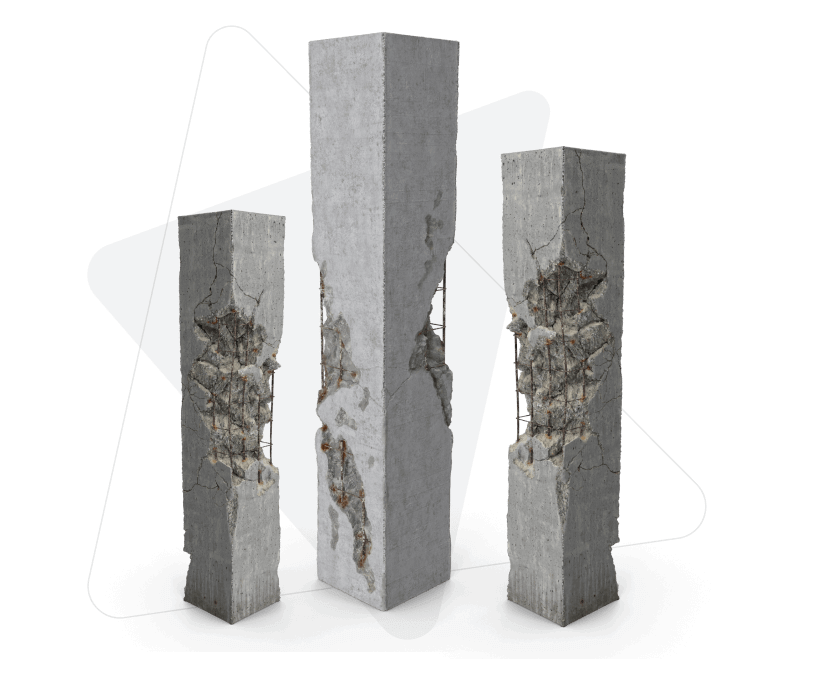

Connecticut DOT – Surface Protection and Significant Reduction in Spalling

In 2003, the Connecticut DOT constructed highway barriers with and without Hycrete admixtures for a comparative analysis. These barriers were installed along Interstate 84 in Connecticut in order to test Hycrete’s effectiveness in concrete protection and corrosion prevention.

The same concrete mix design was used in both cases. The control and Hycrete barriers were alternated to account for potential differences in field conditions. After eight years in service the barriers were tested and carefully photographed. The control barriers showed signs of spalling and exterior deterioration, while the Hycrete barriers remained almost perfectly intact.

The Leading Concrete Protection Strategy for American Infrastructure Projects

Since 2003, Hycrete has increasingly become the go-to solution for protecting critical infrastructure and related construction projects. Now found within bridges, roadways and barriers across the nation, our chemically-advanced admixtures provide comprehensive protection that extends from the surface down to the structural elements. That means better longevity, better sustainability, and a better ROI throughout the transportation industry.