HYCRETE CELEBRATES 10 YEARS OF EXTENDING THE STRUCTURAL AND COSMETIC LIFE OF CONCRETE

FOR IMMEDIATE RELEASE

Media Contact:

Jason Tuerack

(201) 386-8110

jason@hycrete.com

CARLSTADT, N.J., June 14, 2013 – Hycrete Inc., a pioneering manufacturer of integral polymer-forming admixtures, moisture blockers and anti-corrosion agents, is celebrating its 10-year anniversary. Hycrete is proud to partner with our customers in the design and construction of concrete projects through Hycrete’s innovative solutions that extend structural life and save both time and money.

Hycrete is also celebrating the milestone of passing its 1,000th large project mark. Hycrete has been used in major commercial building projects including below-water table basements and foundations, parking structures, tunnels, green roofs, water tanks and podium/plaza decks. Hycrete solutions have been used in infrastructure projects ranging from jersey barriers and bridge decks to sea walls and bridge abutments.

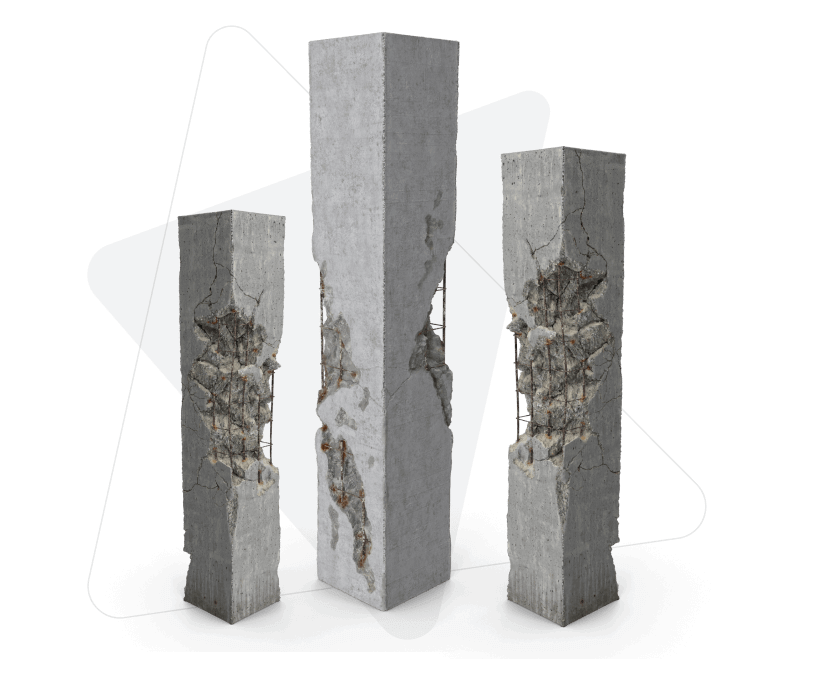

Since water and water-borne salts directly cause most of the deterioration and problems inherent to concrete, Hycrete’s inventors set out to develop a better waterproofing and anti-corrosion agent. Hycrete admixtures have the ability to seal small cracks and fissures, thereby virtually stopping the re-entry of water.

According to Phillip Rhodes, Hycrete Inc.’s Vice President/Executive Director: “Hycrete has been proven to dramatically reduce rebar rust in both un-cracked and cracked concrete. Hycrete greatly reduces spalling caused by freeze-thaw cycling. Also, it significantly retards efflorescence, mitigates sulfate attack and keeps below-water table basements and foundations dry.”

The U.S. Army Corps of Engineers has just completed 5+ years of study on Hycrete. Based on preliminary data, we expect outstanding results. Currently, Hycrete is being field-tested by the USACE in sea walls, sewerage treatment plants and underground aircraft hangers in high sulfate soil. Also, Hycrete has been used in critical water-sensitive portions of New York’s Freedom Tower such as the concrete feeder trenches containing the high power electric feeder cables.

Looking forward to Hycrete’s next decade, Jason Tuerack, Hycrete’s President, stated: “Our challenge is to save developers and DOTs money wasted on costly repairs and help them to increase their earnings or give them the freedom to re-allocate funds from repairs to improvements. By extending the structural and cosmetic life of concrete, I am confident that Hycrete’s customers can reap these benefits.”

Hycrete’s revolutionary technology has been awarded 6 U.S. patents, as well as many international patents. In 2008, Hycrete won a prestigious award when the World Economic Forum in Davos recognized it for being a new game-changing technology.