The effectiveness of any hydrophobic (water hating) admixture depends upon its unique chemical composition. Considering there are many different formulations on the market today, obviously not all hydrophobics are created equal. While Hycrete has undergone rigorous scientific testing and has proven itself in many real-world use cases, there are a number of “competing” admixtures which offer little or no absorption reduction and long-term corrosion protection at all.

For example, there are various admixtures which are essentially hydrophilic (water loving) while claiming hydrophobic performance. That means these admixtures actually attract more water into the concrete to initiate crystalline growth, which then is supposed to protect the internal structure from further water intrusion. Some products require the combined use of a hydrophobic with a hydrophilic crystalline admixture, the process of using these types of products is complicated. Finding test results or case studies to support this approach is difficult.

So why use those products at all? For most projects, unfortunately, it seems to be a case of misleading marketing and lower costs winning out over actual efficacy.

How True Hydrophobic Concrete Admixtures Work

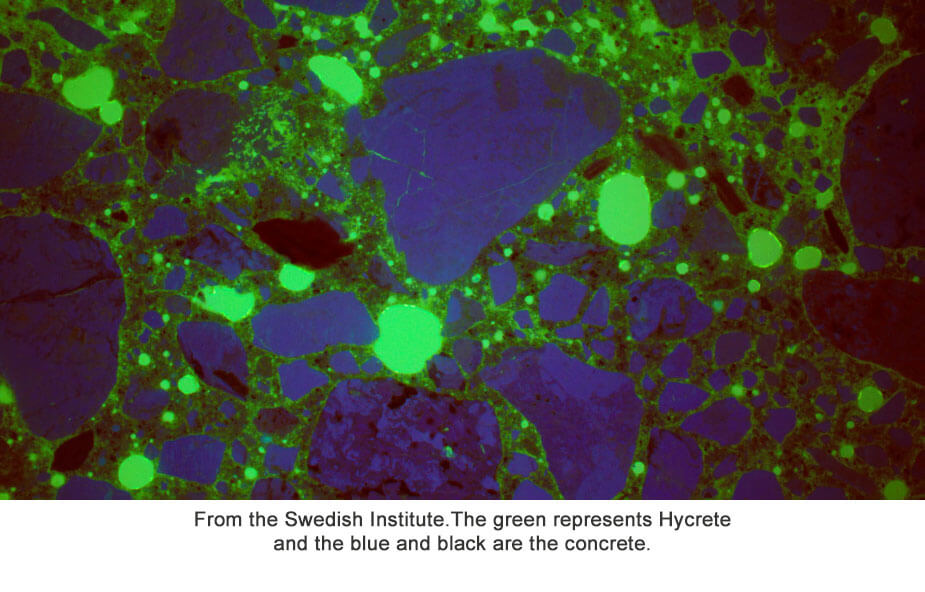

In contrast, Hycrete is a dual-action hydrophobic engineered to keep water out of concrete – from the surface of the structure down to the rebar; from above ground to below grade, including beneath the water table. The unique admixture forms a co-polymer throughout the concrete, filling virtually all pores and capillaries for a truly watertight solution.

Simultaneously, Hycrete reacts with the metallic ions in concrete and rebar to form an internal corrosion-inhibiting surface coating around steel reinforcement. Engineered to extend the lifetime of the structure, no re-application is required for permanent protection.

Understanding Concrete Corrosion and the Need for Hydrophobic Protection

Moisture migration into concrete is the primary cause of concrete degradation and corrosion. That equates to expensive building maintenance costs and extensive repairs down the road. There are two primary water transport mechanisms in concrete: capillary absorption and pressure permeability.

Considering water’s powerful forces and then designing concrete structures to adequately resist the known effects of these two common water transport mechanisms is paramount to achieving durable new construction and preventing corrosion throughout the lifetime of the structure.

- Capillary Absorption – The primary transport mechanism for water in concrete structures, capillary absorption is the movement of water/moisture through the small pores in concrete in the absence of an externally applied hydraulic head. Basically, it’s the result of surface interactions between the water and the pore wall. This is the most powerful means of water movement through concrete.

- Pressure Permeability – Permeability is the movement of water due to a pressure gradient, such as when concrete is under hydrostatic pressure. Water resistance under hydrostatic pressure is a simple function of concrete density, or cementitious content. Concrete’s naturally dense matrix, (of even moderate quality mixes) provides an extremely difficult environment to push water through even under high pressure.This is the least powerful means of water movement through concrete and the easiest to defend.

Nevertheless, a truly effective hydrophobic admixture will further reduce the permeability of concrete structures, which can be especially advantageous for below-grade applications.

Why Other Hydrophobic Admixtures Fall Short:

- Hydrophilic crystalline process actually absorbs water to initiate crystalline growth, meaning more water within the concrete.

- Crystalline growth products do not significantly reduce absorption and require a precise combination of hydrophobic and hydrophilic mixtures within the concrete to meet hydrophobic specifications.

- Hycrete is a single-component, dual-action hydrophobic admixture that delivers comprehensive protection. Unlike crystalline growth products, it requires no additional admixtures to achieve waterproofing and corrosion resistance.

- Hycrete is backed by more than two decades of proven, demonstrable performance. See our extensive Testing Summary page for detailed specifications and test results.

Engineering the Most Effective Concrete Protection Strategy

Hycrete has become the first name in chemically-advanced hydrophobic concrete protection. Our admixtures are rigorously tested and scientifically proven to achieve better longevity, better sustainability, and a better ROI in new construction.