Seawalls pose some of the most challenging conditions faced by modern construction projects. Harsh environments and heavy wear are the norm – the constant impact of waves and water ingress combined with sand shifting, erosion, and chloride corrosion. Withstanding those conditions for decades to come while minimizing maintenance/repair costs requires the use of chemically-advanced concrete materials, engineered for long-term protection, performance, and reliability.

Enter Hycrete. From residential seawall construction to military base installations and other government contracts, our concrete admixtures have emerged as the leader in this unique market.

The Unique Challenges of Seawall Infrastructure

With rising sea levels, the industry will see an increasing need for robust seawall construction that stands the test of time. Essentially, seawalls have to withstand the least favorable conditions possible for reinforced concrete structures. There are the usual challenges of preventing corrosion throughout the concrete material itself and the internal steel rebar, only exacerbated.

Chloride-induced corrosion and rusting rebar are two of the most common issues that arise. Because seawater contains high levels of chloride ions, those problems are only made worse. Sulfate attack is another common mode of failure, and seawater also tends to contain relatively high amounts of sulfate.

Damage from wave action is also common, with sand and debris causing physical erosion of the concrete surface over time. As the surface wears away, the concrete only becomes more prone to further damage and corrosion, accelerating wear and necessitating costly repairs.

Tackling Concrete Corrosion to the Core

Through chloride diffusion testing, Hycrete has been proven to reduce chloride diffusion and extend concrete life. Tourney Consulting Group (TCG) independently performed bulk chloride diffusion testing. The result was Hycrete outperforming both the control and the other waterproofing admixtures by reducing chloride diffusion by a factor of 3.8 to 7.0 times.

When mixed with concrete, Hycrete’s engineered hydrophobic admixture forms a copolymer that fills the pores and capillaries in the material, making concrete virtually non-porous and resistant to moisture.

Furthermore, Hycrete prevents the rust and corrosion of rebar by reaction with the metallic ions in cement and rebar to form an internal corrosion-inhibiting surface coating around steel reinforcement.

Hycrete: Emerging as a Leader in New Seawall Construction Projects

Kuwait Naval Base

Built in the late 1970s, the 1 km breakwater at Kuwait Naval Base (KNB) fell into disrepair. The structure creates an artificial harbor for the portside operations of KNB and supports a roadway allowing traffic to the head of the breakwater, as well as various utilities. As such, a more reliable long-term solution was needed.

The original design mix, initially qualified for breakwater structures with a 25-year serviceable life under splash conditions, underwent adjustments. By incorporating Hycrete as a dual-action corrosion inhibitor and waterproofing admixture, the mix became suitable for pier structures with a 50-year serviceable life under tidal conditions. Samples were submitted for testing to SIMCO and INCO.

Notably, the conventional approach of service life analysis was replaced by STADIUM, a sophisticated numerical modeling tool. STADIUM considers many unique factors such as chloride ingress and other contaminants. These parameters are carefully worked with concrete degradation kinetics to estimate the time before reinforcing steel corrosion initiation. The result was that Hycrete met all requirements of the contract.

U.S. Army Corps of Engineers Evaluation

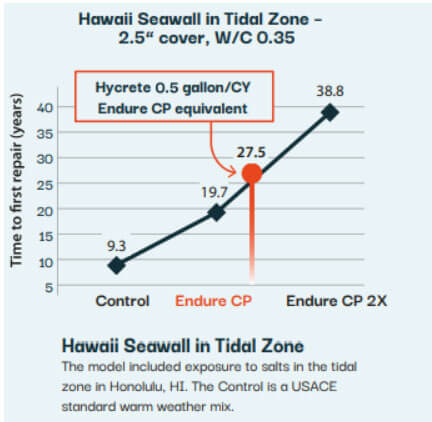

A life-cycle durability study focused on the potential benefits of using Hycrete was conducted under a research grant funded by the U.S Army Corps of Engineers(USACE). This study used the U.S. Army Corps of Engineers Life 365™ Modeling in Various Applications and Climates.

In independent modeling performed by Tourney Consulting Group (TCG) , the durability of concrete with Hycrete admixtures was compared to standard control concrete mixes used by USACE. The Life 365™ analysis predicted the time in years until the first repair and the cost effectiveness when using Hycrete. It concluded that in all scenarios Hycrete significantly increased the time until first repairs and provided significant cost savings.

Here are summarized results from the study in various climates including seawalls in Hawaii:

Gulf Coast and Florida Seawall Construction Projects

While all of the coastal states will no doubt see an increasing demand for new seawall construction as sea levels rise, it’s Florida, Texas, and the entire Gulf Coast that’s likely to be at the top of the list. Frequent extreme weather events and extended hurricane seasons will only exacerbate the issues with the long coast and abundance of low-lying inland communities.

Of course, the Department of Environmental Protection (DEP) carefully regulates the construction and maintenance of seawalls and virtually all other shoreline stabilization structures. Hycrete has a long history of working closely in accordance with local environmental regulations to protect waterways, beaches, and inland property – throughout the Gulf Coast region and beyond.

The Most Effective Concrete Protection for Seawall and Breakwater Projects

Hycrete has become the first name in enhanced concrete protection for seawalls, breakwaters, and other marine infrastructure projects. Our chemically-advanced admixtures provide new construction with comprehensive protection that extends down to the core of the structure. That means better longevity, better sustainability, and a better ROI.