Water processing plants and wastewater treatment facilities pose a number of unique challenges to builders.

Typically in construction, water and concrete do not play well together: the concrete material breaks down, the steel rebar rusts and corrodes… Overall, the life of concrete structures tends to be significantly reduced in exceptionally wet environments. Obviously, wet environments come standard in facilities designed to treat and process water – not to mention a long list of potentially corrosive chemicals.

Enter Hycrete – the most chemically-advanced waterproof concrete admixture in the waterworks industry. From municipal drinking water treatment to industrial wastewater processing, from desalination plants to water reclamation facilities and high-tech data centers, Hycrete maximizes the lifetime as well as the ROI of new construction, all while helping builders reach their sustainability targets.

The Common Concrete Failure Modes for Water Processing Facilities

First, let’s take a look at why advanced waterproofing is crucial for these facilities. Though concrete is high in strength, it’s relatively porous and alkaline. That permeability means the structure is constantly prone to water intrusion, as well as chemical deterioration – most notably chloride corrosion.

- Water Ingress – The porous nature of concrete leaves it open to water ingress, along with all of the various chemicals found in water/wastewater and the processing of it. Over time the cement paste tends to break down, weakening the structure from the inside out. Water ingress issues are only exacerbated by extreme thermal cycles or fluctuations in temperature – not uncommon in water processing.

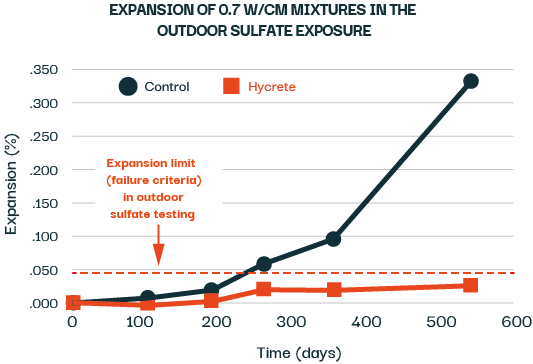

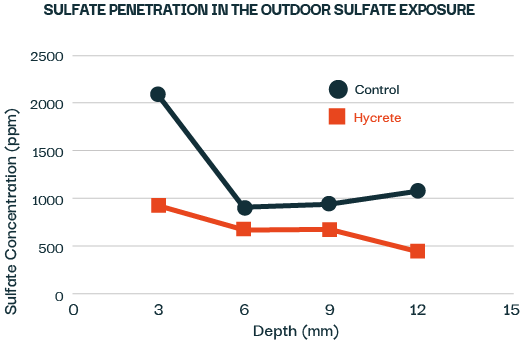

- Chemical Corrosion – Along with water intrusion comes chemical attack. Especially in wastewater treatment, various chlorides and sulfates are encountered which can quickly lead to concrete corrosion issues. A common effect is carbonation, which lowers the pH level of the concrete, thus accelerating corrosion of internal steel reinforcement elements.

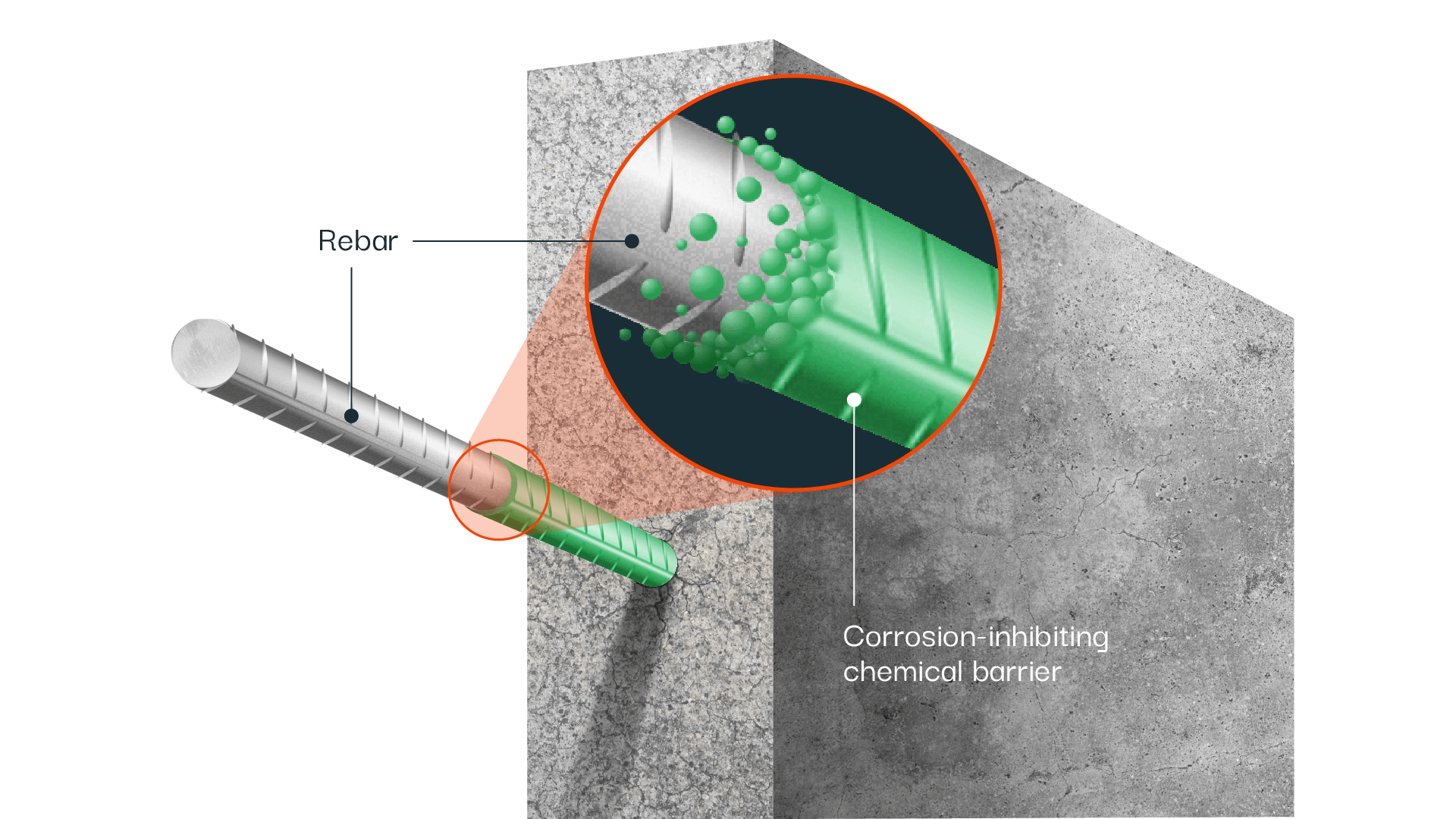

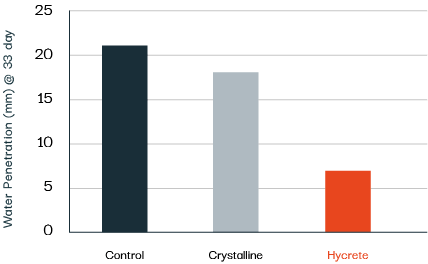

A uniquely engineered hydrophobic admixture, Hycrete eliminates both issues at the source. Unlike competing crystalline growth admixtures, which actually require water ingress, Hycrete keeps water from getting past the concrete surface.

The Need for Better Concrete Materials in Water Treatment Plants:

Municipal Water Processing and Wastewater Treatment Plants

Holding tanks, sludge tanks, and any interconnected concrete piping in municipal water treatment plants all demand advanced waterproofing. These components are constantly subjected to potential concrete chemical attack from the use of various conditioners, coagulants, flocculants, and other chemicals. Inadequate waterproofing thus results in all-around steady deterioration that requires expensive facility maintenance and repairs.

Desalination Plants

One of the worst environments for concrete and steel rebar is salt water, so desalination plants pose a special challenge. Here, many concrete structures will be in direct contact with chlorides – and Hycrete is the most effective strategy against chloride intrusion and corrosion.

Extensive testing of Hycrete Endure CP in accordance with ASTM G109 has proven its efficacy. After 100 weeks of wet/dry cycling in 15% salt water, visual inspection showed no brown staining on concrete samples treated with Hycrete, as well as no corrosion of the rebar. The control and competitor samples all showed brown staining on the surface along with significant corrosion of the rebar in this same period.

Industrial/Agricultural Water Processing and Reclamation

Industrial wastewater processing and water processing systems for farms (irrigation, fertilizer runoff, etc.), as well as virtually all types of water reclamation systems also see significant long-term advantages with Hycrete’s advanced waterproofing properties.

Manufacturers, agricultural enterprises, and industrial operations of all types need to maximize their ROI on any facility investments in order to remain cost competitive. That means maximizing the structural service life and minimizing any required maintenance – which is expensive in itself while also requiring cost-eating downtime. By preventing water ingress, Hycrete reduces the ongoing need for concrete restoration and repairs, leading to significant cost savings over the facility’s operational life.

New Data Center Construction

Data centers are on the rise. In fact, it’s been estimated that data centers now claim roughly 25% of all new commercial construction. Of course, advanced water treatment systems are integral within data centers, which generate both wastewater and cooling effluent.

As the first name in high-tech concrete construction, Hycrete is increasingly working with builders throughout the industry to serve the nation’s booming need for new data center construction. See our Case Study on a data center project for the WA State Information Services (DIS) in Wheeler, Washington.

Enhanced Concrete Materials to Meet the Requirements of Water Processing Facilities

Hycrete is an innovative American manufacturer founded in 2003. Our company’s mission is to help the construction industry build better, more sustainable structures through the engineering of better concrete materials. Backed by more than two decades of experience and thousands of successful projects worldwide, Hycrete has become the scientifically proven gold standard for concrete waterproofing and corrosion protection.