Concrete is the second most widely used building material in the world, with water being number one. Concrete is globally accessible, and it is versatile both structurally and aesthetically. However, concrete needs supporting materials to meet building codes and requirements. Many of these supporting materials increase embodied carbon output during construction. The most frequently used supporting building material on the market is sheet membrane waterproofing, but it comes with substantial negative environmental impacts and costly limitations.

Membrane Treated Concrete is Non-Recyclable

Concrete waterproofing failures comprise more than $22 Billion in repairs annually in the US alone. Combining that with membrane treated concrete being non-recyclable at the structure’s end of life, membranes have now increased the detrimental environmental impacts years down the road. How do we extend a structure’s life and reduce impending disastrous risks due to corrosion caused by membrane failures while protecting our environment for future generations?

Advanced Concrete Protection with < 1% Water Absorption

Over two decades ago, the founders of Hycrete agreed that conventional concrete protection was no longer meeting the demands of modern structures and construction methods. Solutions that were higher performing, easier to install, cost less, and more environmentally sustainable were needed. Scientists by training, Hycrete’s founders leveraged proven science to formulate an advanced chemical admixture that makes concrete molecularly waterproof and corrosion-resistant. The resulting hydrophobic liquid admixture polymerizes in concrete, making it virtually non-porous, transforming the concrete into a waterproof membrane. This advanced concrete technology limits water absorption to < 1%, prevents the corrosion of steel reinforcement, and contributes to sustainability goals.

Hycrete is Cradle To Cradle Certified

Hycrete’s technically advanced products are the most sustainable concrete solutions available on the market. The very first building material ever certified Cradle to Cradle, Hycrete products adhere to the very highest standards of sustainability. As commercial construction methods continue to modernize, advanced sustainable solutions have become the industry standard. Hycrete’s proven technology exceeds those demands — representing the past, present, and future of concrete protection.

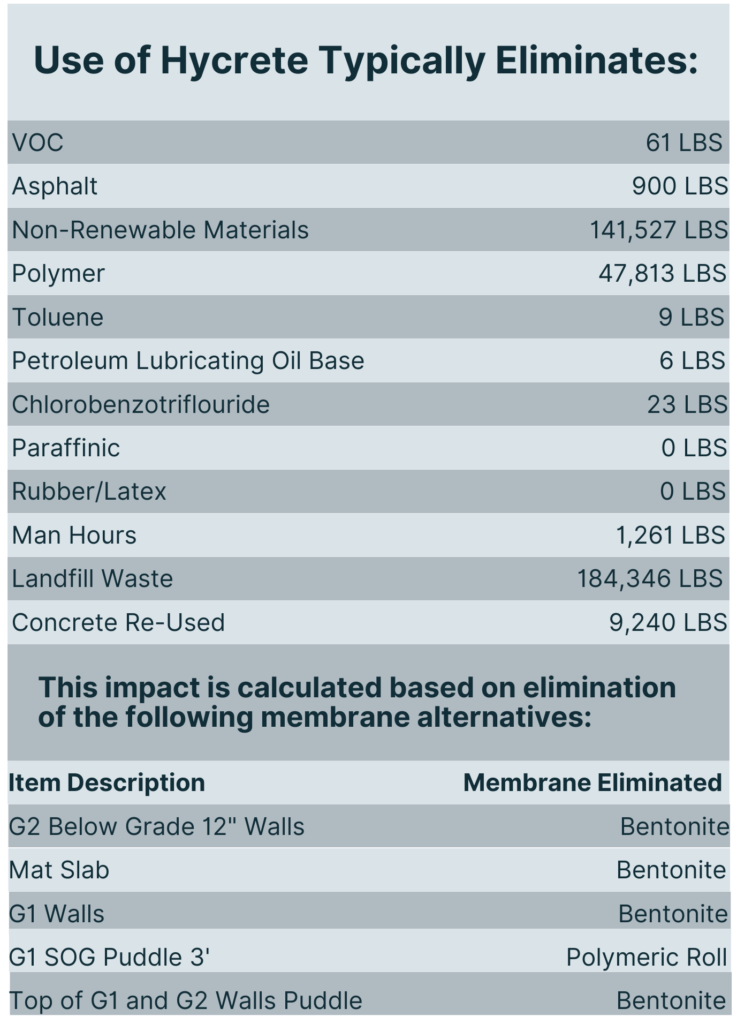

By eliminating the use of outmoded membranes, you also reduce added site storage, membrane construction waste, membrane delivery, installation labor, and non-recyclable concrete.

With Hycrete, it’s simple, if you can pour concrete, you can waterproof it.

Hycrete eliminates a broad range of environmentally undesirable effects, quantified in the model below.

NOTE: Hycrete has compiled data from six industry-leading concrete waterproofing membranes/coatings using public product data and materials safety data sheet information to quantify the environmental savings.

Launched in 2003, Hycrete undergoes extensive laboratory and field testing to confirm its superior performance. 20+ years and thousands of successful projects worldwide, Hycrete is the scientifically proven gold standard for concrete waterproofing and corrosion protection.

To learn more about the sustainable benefits of Hycrete click the button below.