How Hycrete Technology Works

Simply Better Concrete Protection

Armed with our chemically advanced, dual action corrosion inhibitor, Hycrete makes your structures more durable, increases life-cycle, and increases sustainability.

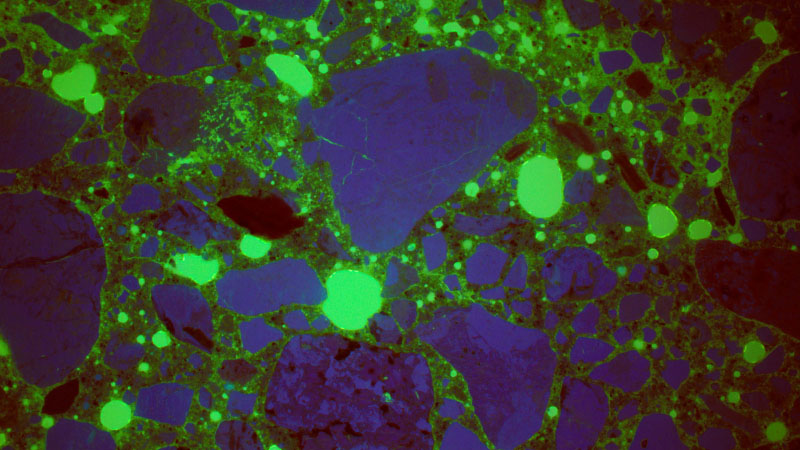

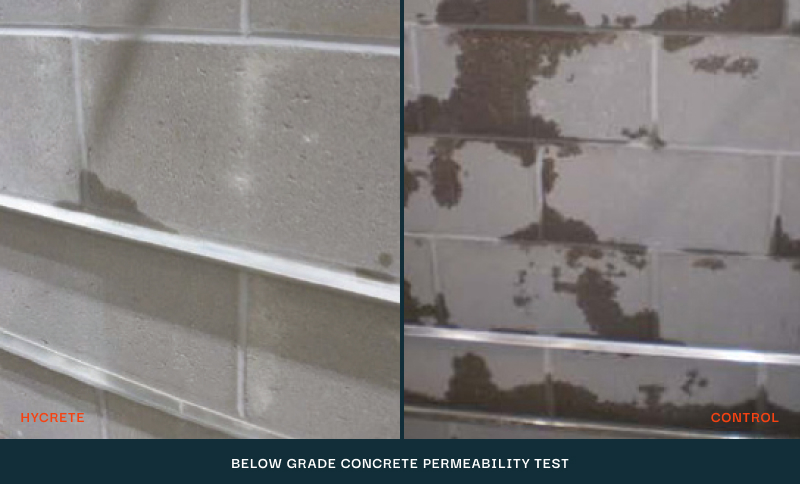

The Problem With Concrete

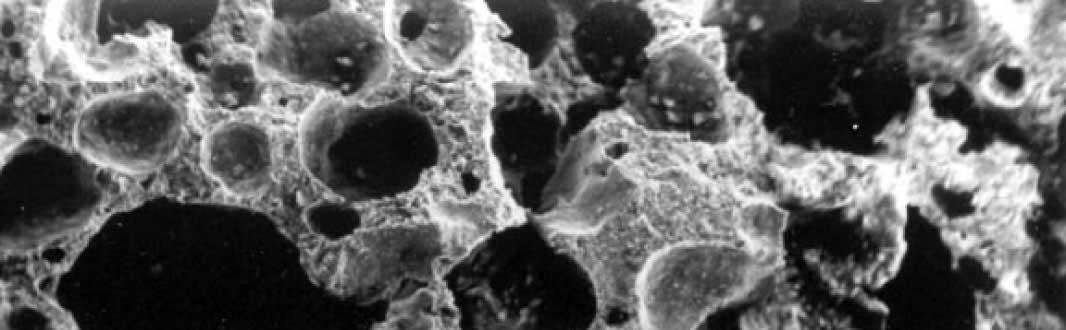

Concrete is like a hard sponge.

Although concrete appears to be a solid mass, its physical structure at the microscopic level more closely resembles a hard sponge — porous, with an extensive network of capillaries — making it vulnerable to the damaging effects of water and chloride ingress.

Legacy Concrete Products Are Not Getting the Job Done

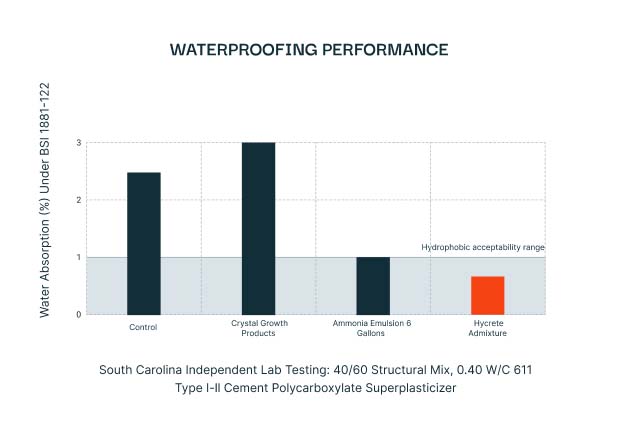

Traditional concrete waterproofing products can mitigate, but do not fully solve the challenge of concrete porosity.

Hycrete Technology

Concrete Science That Gives You a Major Advantage

hy·crete | \hi-kreet\

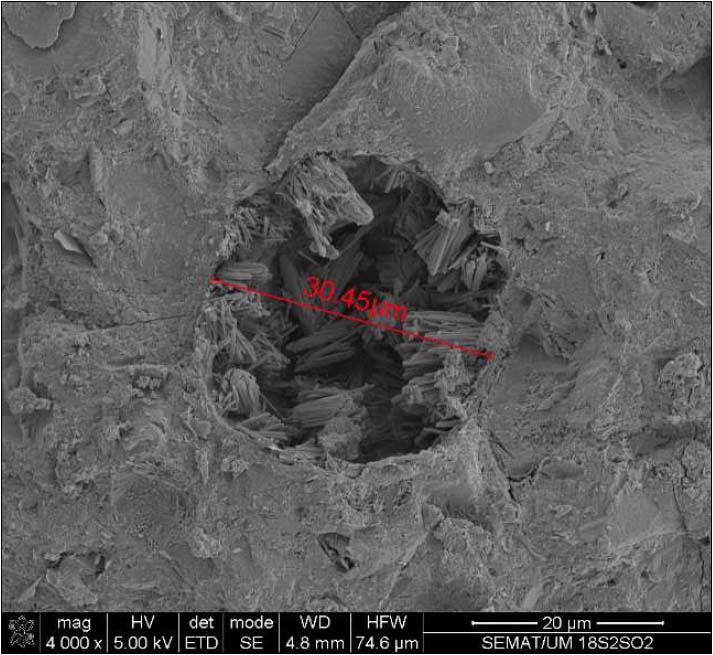

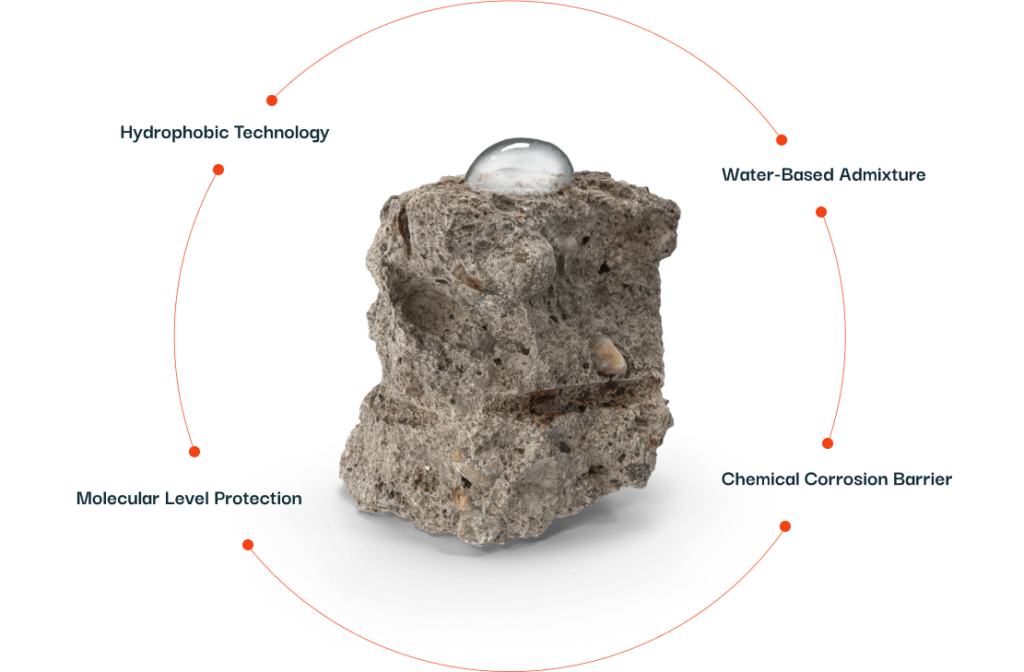

Molecular Level Protection Inside Your Concrete

: A hydrophobic (water-repelling) liquid admixture that forms a performance copolymer when mixed with concrete that fills its natural capillary system, making concrete virtually non-porous and resistant to the transport of moisture vapor and liquid.

A chemically advanced hydrophobic liquid admixture that reacts with metallic ions in cement and rebar to form an internal corrosion-inhibiting surface coating around steel reinforcement.

A water-based admixture for the protection of concrete that extends the life-cycle of concrete structures, allows post-life concrete to be recycled, and earns valuable LEED credits for green building projects.

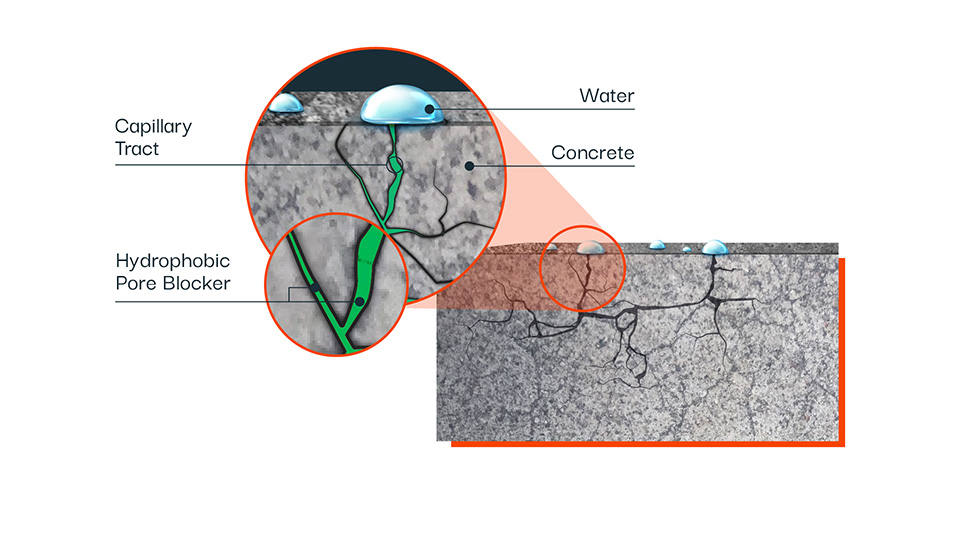

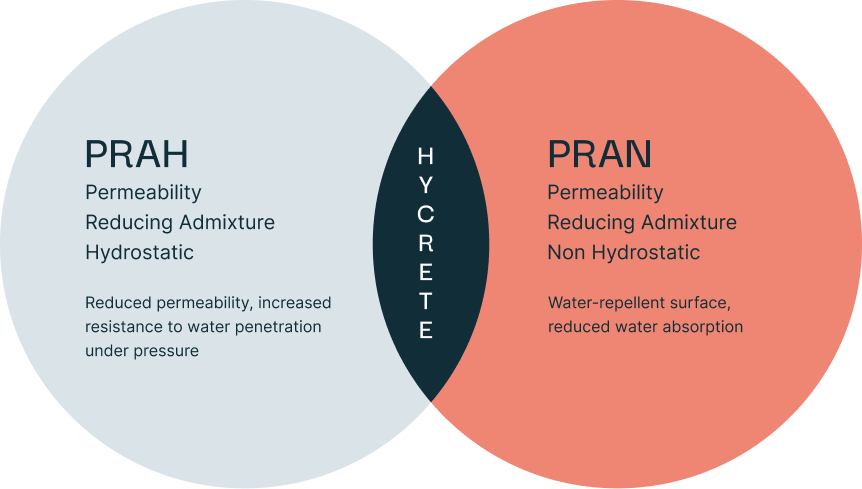

Water Protection Science

Hycrete’s patented waterproofing technology offers a unique hydrophobic solution.

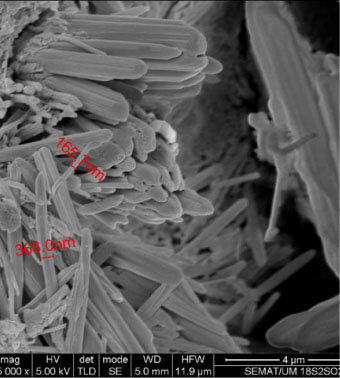

Hydrophobic Barriers in Concrete

The image above is from fluorescence microscopy testing conducted by the Swedish Concrete Research Institute. This cross section of Hycrete treated concrete demonstrates that the natural pores and capillaries are completely filled with hydrophobic polymers, creating a highly effective moisture barrier inside the concrete itself.

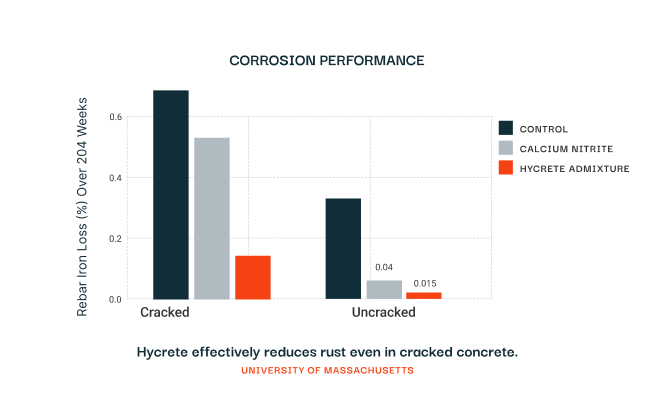

Corrosion Protection Science

Chemical corrosion protection for steel reinforcement that forms inside your concrete.

Liquid Green Bar: Corrosion Inhibiting Chemical Barrier

Known as “liquid green bar,” Hycrete chemically reacts with metallic ions in steel reinforcement to form a corrosion-inhibiting chemical barrier around rebar. Unlike epoxy coated rebar, Hycrete protection is not susceptible to dings, holes, or imperfections, and does not degrade over time.

how hycrete360 helps

Protect. Simplify. Support.

Hycrete technology makes concrete waterproof on delivery and ready to pour, allowing you to build better structures that are higher performing, more sustainable, and lower cost than those with legacy concrete waterproofing.

Highest Performing

Hycrete reduces water absorption in concrete to less than 1%, the highest performaing technology on the market.

Dual Protection

Not only is Hycrete the most waterproof concrete technology available, it also prevents corrosion of steel reinforcement.

More Sustainable

With a longer life-cycle and smaller carbon footprint, Hycrete is Cradle to Cradle Gold certified for a positive environmental impact.

More Durable

With a longer life-cycle and smaller carbon footprint, Hycrete is Cradle to Cradle Gold certified for a positive environmental impact.

Lower Cost

Hycrete generally costs 20-30% less than an installed membrane. It’s longer life-cycle ensures greater long term ROI.

Push Button Dosing

As a liquid concrete admixture, Hycrete is incredibly easy to dose, mix, and deliver, with consistent quality performance.

How to Get Started

Concrete Protection From the Inside Out

Our proven 3-step process provides everything you need to build with better concrete.

- Simplify Your Process

- Minimize Your Risk

- Reduce Your Costs