Hycrete News & Media

Beyond Litigation: How Forward-Thinking Builders Use Waterproofing as a Competitive Advantage

Lindsey Montgomery June 27, 2025

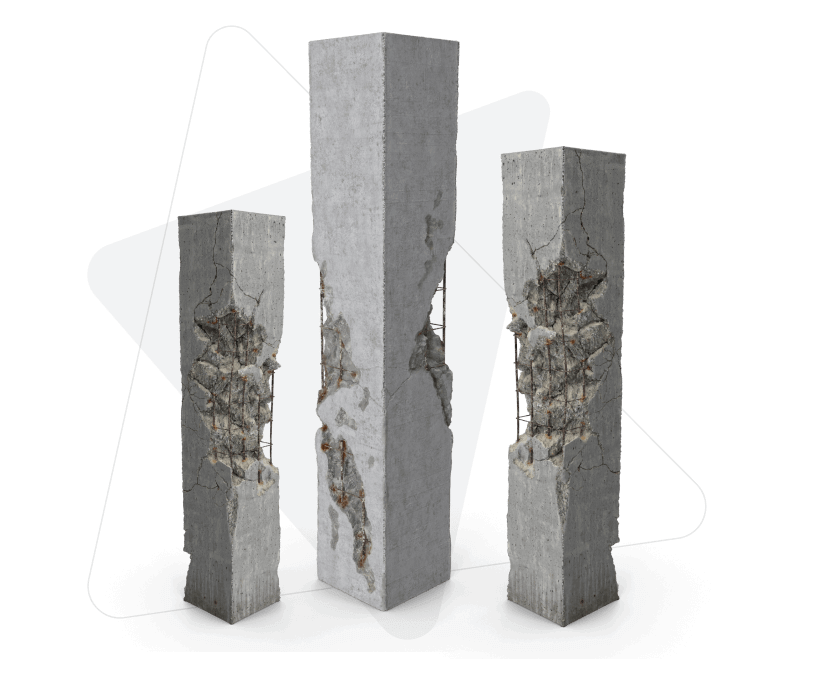

In our previous article, we explored how waterproofing failures are one of the top causes of construction litigation—and how Hycrete’s integrated waterproofing system helps commercial

Concrete News

Stay Informed

Hycrete’s once monthly e-news keeps you informed on current industry standards and news. Unsubscribe at any time.

How to Get Started

Don’t Just Protect It, Hycrete It

Our proven 3-step process provides everything you need to build with better concrete.

- Get Reviewed

- Get Protected

- Get Supported