Hycrete Meets NSF/ANSI 61 Criteria for Drinking Water Projects

FOR IMMEDIATE RELEASE

Media Contact:

Jason Tuerack

(201) 386-8110

jason@hycrete.com

View PDF – Hycrete Press Release – Hycrete Approved for Use in Potable Water Applications

View PDF – Hycrete Press Release – Hycrete Approved for Use in Potable Water Applications

CARLSTADT, N.J., September 11, 2013 – Hycrete, Inc., a leader in waterproofing and corrosion protection technologies for concrete, is proud to announce the approval of its concrete admixtures in potable water applications. Hycrete admixtures were tested in accordance with NSF/ANSI 61 for use in concrete pipes and water tanks containing drinking water. The NSF approval is highly regarded by engineers locally as well internationally in water treatment facilities.

South Barrington, IL

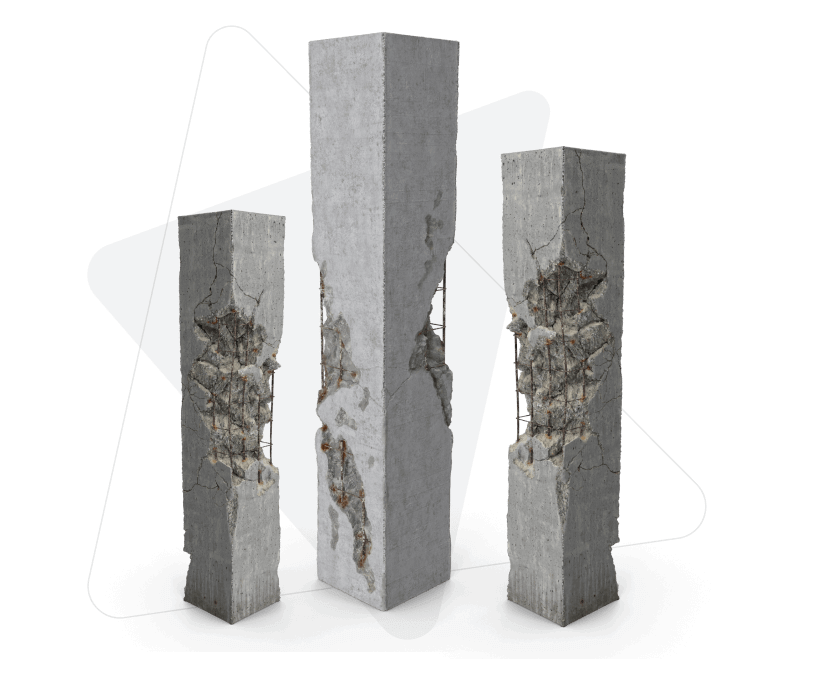

Hycrete admixtures are used to waterproof concrete structures and protect steel reinforcement from corrosion. Hycrete admixtures are used in water tanks, concrete pipes, and water treatment facilities to maximize durability and save time and money. Using Hycrete admixtures in place of exterior membranes and coatings can save 30% or more on cost and save several weeks on the critical path.

Hycrete has been used in a variety of water and wastewater treatment tanks as a long- term solution for maximum durability, such as the Woods of South Barrington Community potable water tank in South Barrington, IL. By reducing water and chemical absorption into concrete, and by coating steel reinforcement, Hycrete admixtures provide a dual mechanism for corrosion protection. In addition, by providing integral protection throughout the concrete, there is no need to re-apply costly coatings and exterior membranes.

According to Fazal Wahab, Hycrete, Inc.’s Director of Research and Development, “Hycrete has proven to be a cost-effective solution for long-term durability and waterproofing in concrete tanks and pipes. Because of the up-front cost savings and Hycrete’s successful track record, the company is rapidly expanding its growth in the water and wastewater treatment market.”

For information specific to Hycrete’s NSF/ANSI 61 approval, please visit the NSF website (www.nsf.org). For more Hycrete information, please visit www.hycrete.com.