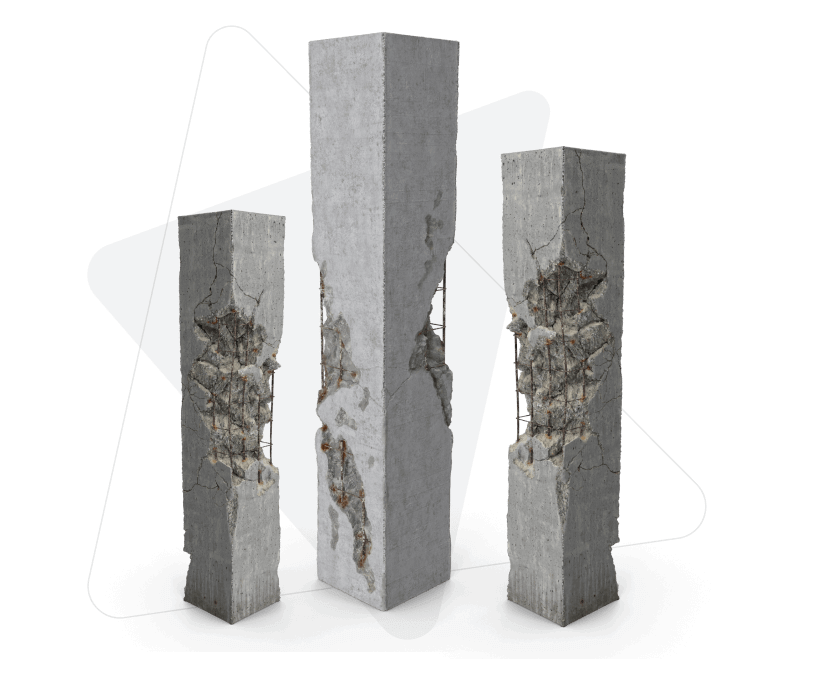

As port authorities and government agencies continue to invest in more resilient infrastructure, concrete waterproofing and corrosion protection remain top priorities – as well as long-term sustainability.

Engineered to satisfy all three of those requirements, Hycrete has been officially approved for use by the U.S. Army Corps of Engineers (USACE) following rigorous testing under ASTM C494 and ASTM C1582 standards.

Independent validation by the USACE Engineer Research and Development Center – Construction Engineering Research Laboratory (ERDC–CERL) demonstrated Hycrete’s exceptional ability to prevent water penetration and extend the life of concrete masonry structures. The proven performance makes Hycrete the ideal solution for port expansions, marine terminals, and defense-related construction – all of which demand the ultimate in long-term structural integrity.

For port commissioners and contractors evaluating materials that deliver long-term performance and reduced maintenance – specifically in wet, potentially salt-laden environments – Hycrete offers USACE-approved protection that combines superior structural durability with substantial lifecycle cost savings.

Meeting the Rigorous Standards of USACE-Approved Concrete

The USACE undertook independent testing to evaluate Hycrete’s hydrophobic admixture in concrete masonry applications. This assessment was grounded in ASTM C494 (chemical admixtures in concrete) and ASTM C1582 (water absorption testing) – established standards that measure admixture performance and water penetration characteristics respectively.

The testing showed that Hycrete meets and exceeds these rigorous benchmarks, earning its place as an approved solution for military-grade infrastructure. See a complete overview of testing, certifications, and approvals in the Hycrete Testing Summary.

ASTM E514 Testing Summary

The ERDC–CERL performed a series of advanced tests in their study: Water Penetration of Masonry Walls with a Hydrophobic Additive. They carefully evaluated the water resistance of concrete masonry walls incorporating Hycrete admixture versus standard untreated walls. Testing followed ASTM E514 which simulates wind-driven rain conditions.

Time to dampness:

- Standard masonry – Average of 10 minutes

- Hycrete-treated masonry – Average of 3.2 hours

Visible water penetration:

- Standard masonry – Average of 14.5 minutes

- Hycrete-treated masonry – No visible water penetration

Area of wall surface dampness:

- Standard walls – 17.4% to 36%

- Hycrete walls – 0.024% to 0.105%

Total water collected behind walls:

- Standard walls – Average of 6.3 liters

- Hycrete-treated walls – 0 liters

These exceptional results confirm that Hycrete significantly improves resistance to water penetration, offering robust protection for structures exposed to severe weather or high-moisture environments.

An ASTM C494 and ASTM C1582 Certified Concrete Corrosion Inhibitor

Additionally, Hycrete’s classification under ASTM C494 as a Type S (Specific Performance) admixture confirms its superior functionality in both waterproofing and corrosion resistance. Hycrete’s ASTM C1582 certification further confirms that treated concrete exhibits dramatically reduced capillary absorption, a key indicator of water ingress resistance. Together, these standards validate Hycrete’s role not only in performance but also in compliance and reliability for military-grade construction.

As a proof of concept, see our Case Study on the Kuwait Naval Base, in which Hycrete was instrumental in reaching the military’s 50-year durability goals.

Superior Concrete Waterproofing and Corrosion Protection for Critical Projects

Our team is extremely proud of the U.S. Army Corps of Engineers’ recognition of Hycrete’s technology as a high-performance, cost-effective solution for moisture protection. Backed by ASTM C494 and C1582 certifications, and validated by ASTM E514 field testing, Hycrete stands ready to protect the ports, naval bases, and other mission-critical structures.