Case Study

University of Washington Medicine

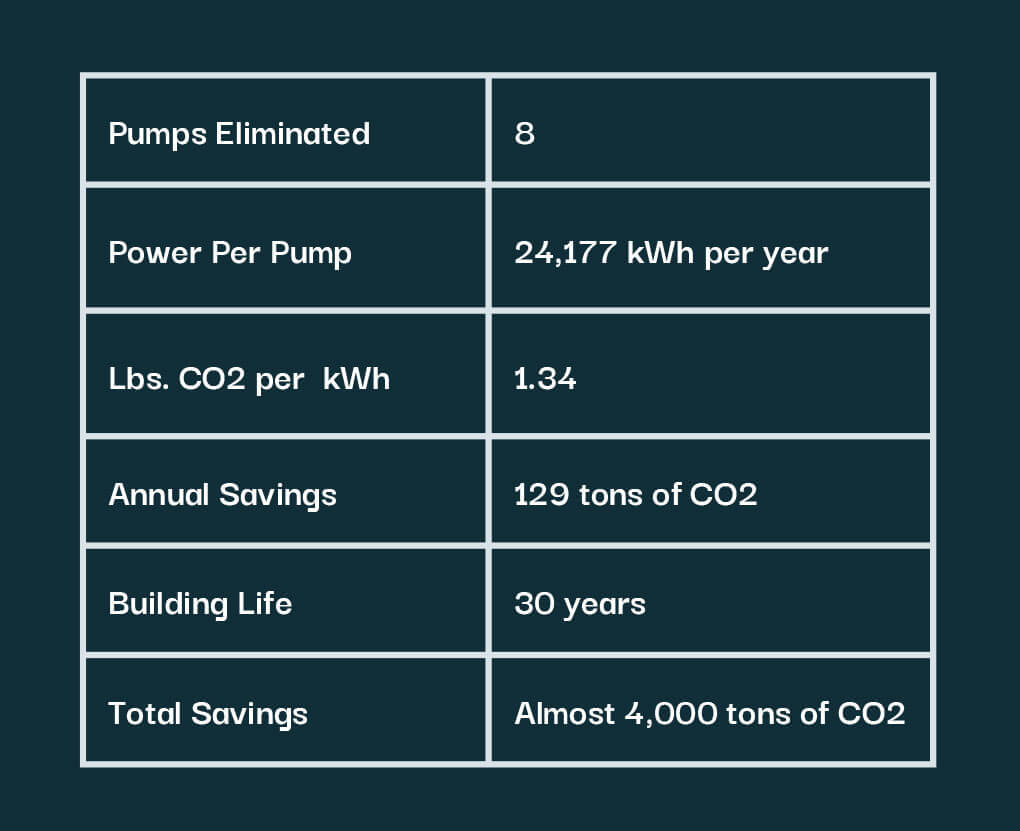

Hycrete Saved 4,000 tons of CO2 by EliminatingDe-Watering Pumps for UW Medicine.

HYCRETE360 PROVIDES SUSTAINABLE LONG-TERM CONCRETE PROTECTION

Structure: 2 Lab Buildings, 1 Office Building, and Below Grade Parking

Applications: Foundation Walls, Structural Slab, Fire Suppression Tank,

Temporary Roof, Elevator Pits

Owner: UW Medicine

Developer:

Vulcan Real Estate

Architect:

Perkins + Will

General Contractor: Sellen Construction

Engineer: MKA

Ready Mix Provider: Stoneway Concrete

Introduction

U.W. Medicine Phase II consists of two five story laboratory buildings and

one five story office building. The buildings are above three floors of

below-grade parking and located in the South Lake Union District in

downtown Seattle.

Challenge

To meet the parking requirements for the project, the lowest parking level

had to be constructed eight feet below the existing water table,

necessitating a solution capable of withstanding high hydrostatic

pressure.

Solution

Hycrete360 (formerly System W) offered superior performance to other

waterproofing systems, was more cost-effective and accelerated the

construction schedule. Using Hycrete360 eliminated the need for

waterproofing membranes and saved Sellen Construction approximately

$150,000 up front in material savings.

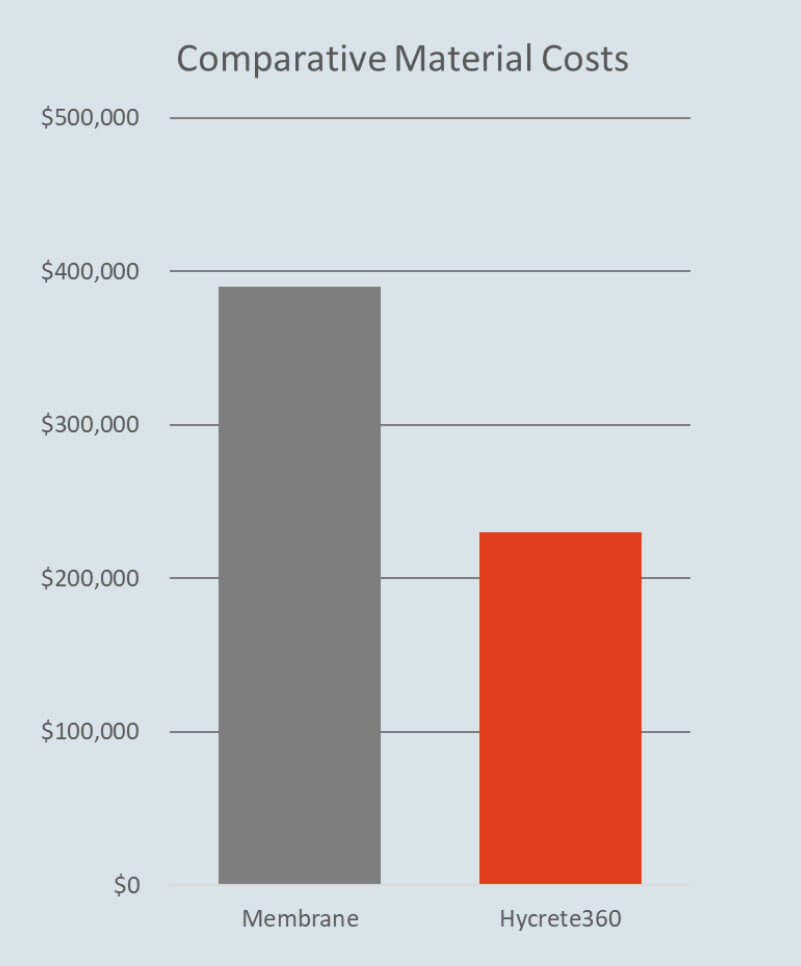

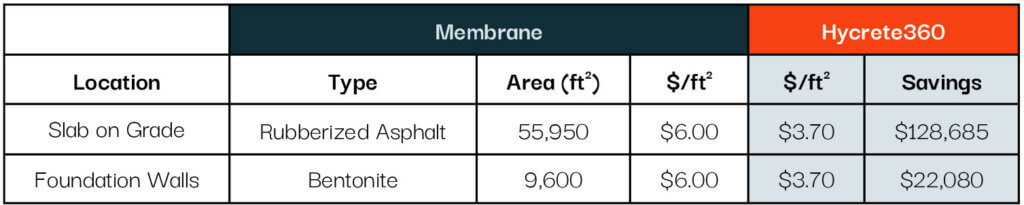

Material Savings

Total Material Savings = $150,000

Using Hycrete360 proved to be the most cost effective way to waterproof the structure. Hycrete was chosen because it did not have any negative effects on the workers placing the concrete and there were no environmental concerns associated with its use.

Jack Avery,

Senior VP, Director of Construction

Sellen Construction

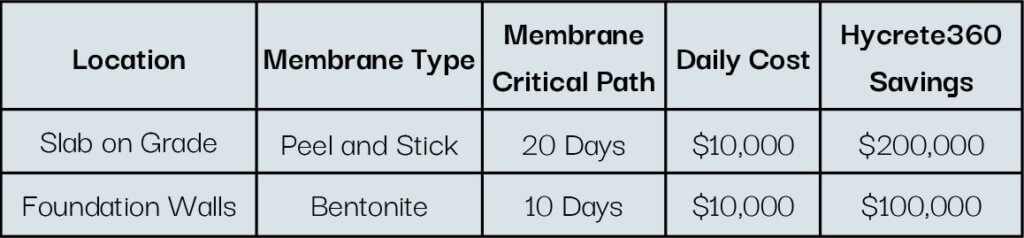

In addition, using Hycrete360 saved 30 days on the critical path (20 days on the slab on grade and 10 days on the foundation walls), totaling $300,000.

Time Savings

Total Time Savings = $300,000

Result

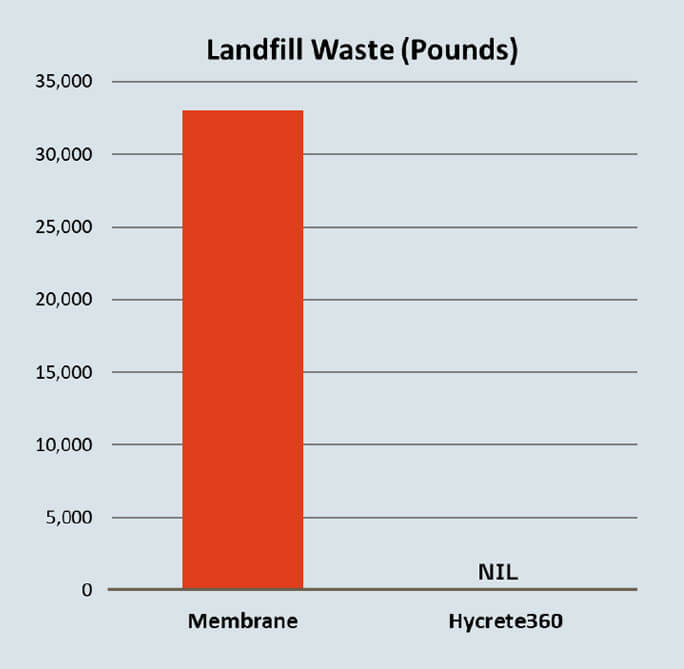

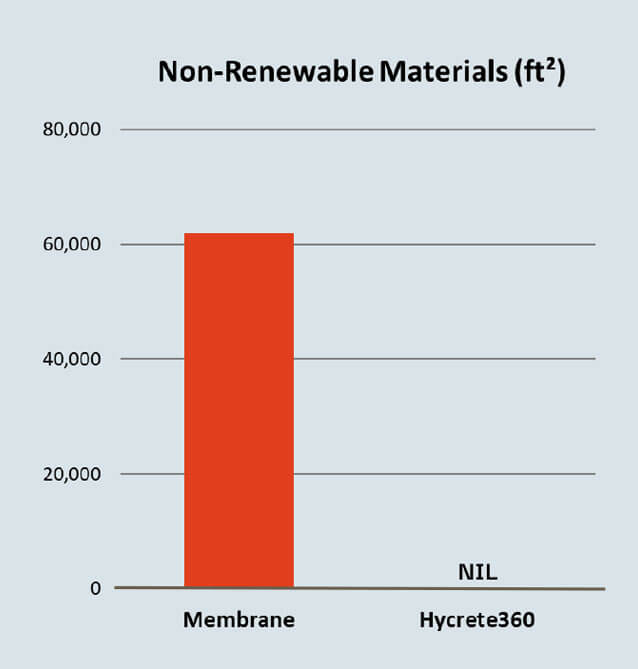

Total material and time savings are $450,765. On top of CO2 savings associated with eliminating de-watering pumps, eliminating waterproofing membranes saved over 33,000 pounds of landfill waste,

16,000 pounds of asphalt, 1,100 pounds of VOCs (volatile organic

compounds), and 62,000 square feet of non-renewable materials.

Solution

If a membrane is used behind a wall or under a slab, there is no way to repair it if it develops a leak. Water will continue to travel to find the nearest crack. When there is a breach in waterproof concrete you know where the problem is, and it can be addressed.

Jack Avery,

Senior VP, Director of Construction

Sellen Construction

More Case Studies

Thousands of Success Stories Worldwide

Hycrete’s proven technology has protected thousands of structures worldwide.

How to Get Started

See How Hycrete Can Impact Your Project

Let our in-house team assist. Our proven 3-step process provides everything you need to build with better concrete.

- Get Reviewed

- Get Protected

- Get Supported